- Toolsidee.co.uk >

- < Metal benders >

- HBM ub 1 metal bender

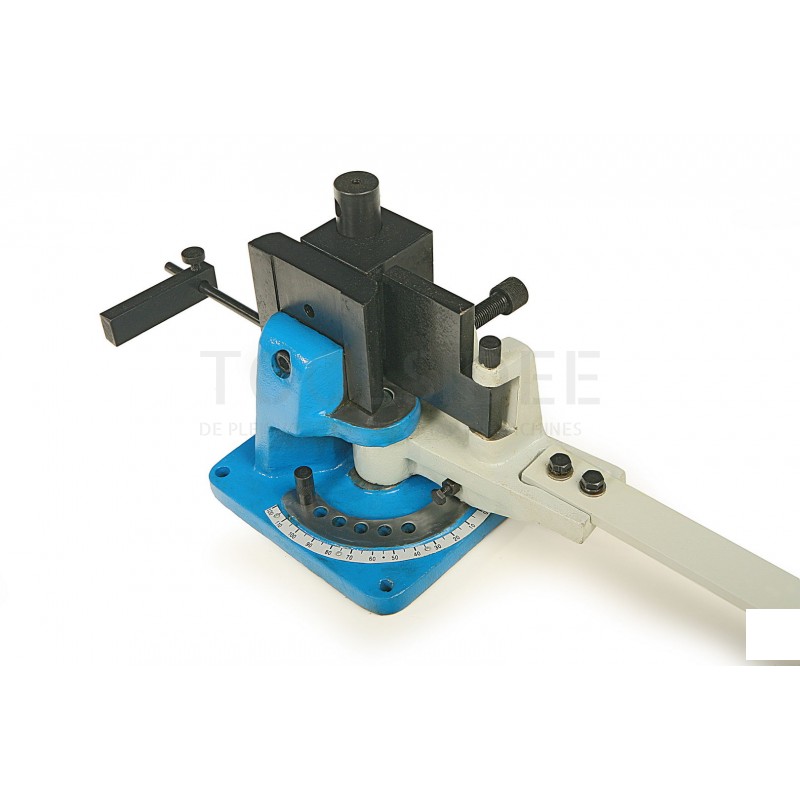

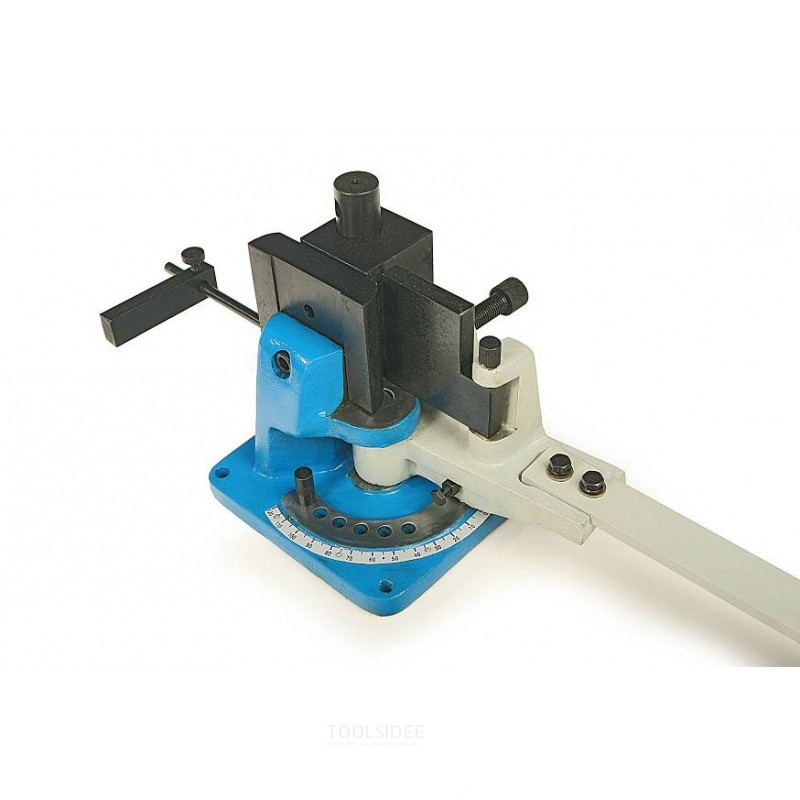

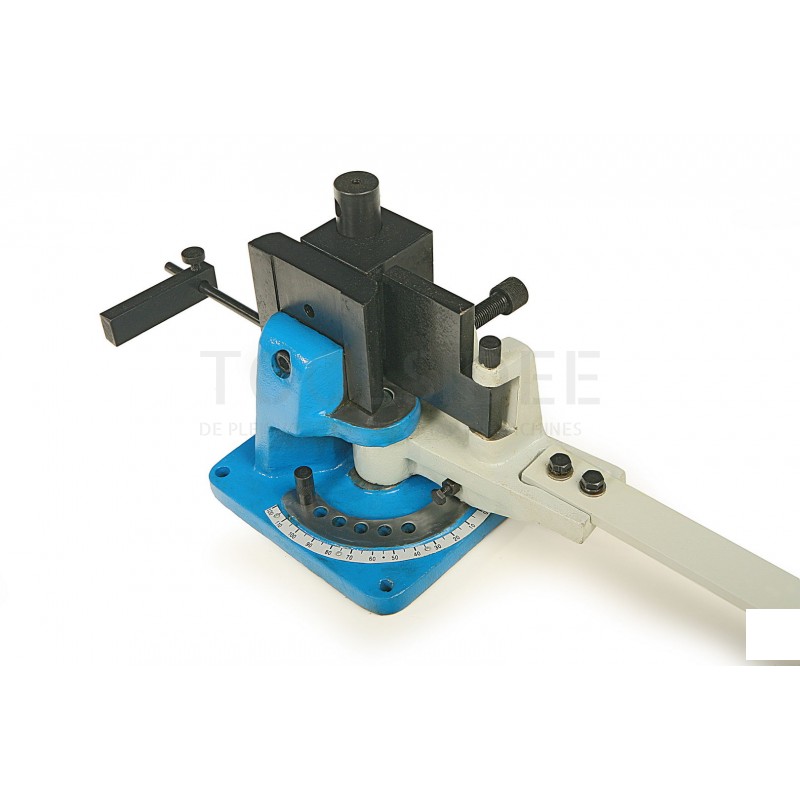

HBM ub 1 metal bender

Out of Stock

- Description

The UB-100 is suitable for bending solid bars and profiles.

You can bend both hot and cold with a bending angle of 120 degrees.

The machine is equipped with eccentric fast-tension for fast pinching of the material.

Due to the solid construction and adjustable angle stop, high accuracy can be achieved.

There is also a length stop present.

Technical details of the HBM UB 1 metal bending machine.

Warm bending: 100 x 15 mm.

Warm bending: 60 x 20 mm.

Warm bending: 35 x 25 mm.

Warm bending: 28 x 28 mm.

Warm bending: 30 mm.

Warm bending: 100 x 15 mm.

Placement of the Machine.

- The machine can best be mounted on a sturdy workbench or free-standing column. It is also possible to provide the underside with a angle iron with 2 bolts so that the machine can quickly be placed in a vice on chore.

Setting the machine.

- Place the required bending jaw in the machine and place the material against it.

- Then pull the bending lever against the material.

- Then tighten the first bolt until the bending plate is parallel to the material.

- Then optionally set the length and angle stops.

- And the machine is ready to bend.

Bending of narrow material.

- When bending narrow sheet material, it is recommended to work square and round in the center of the bending jaw.

Choosing the bending angle.

- If possible, choose the greatest possible bending radius so that the required elongation in the material can be kept as small as possible.

- This means less breakage in the end product.

Article number: 820-E

Note: Import Taxes and Duties still need to be paid for shipments to Norway, Switzerland

Write a review

You help others with their choice by sharing your experience.

Related products

Fast shipping throughout Europe!

Fast shipping throughout Europe!  Reflection period 14 days

Reflection period 14 days  Delivery times 1 - 3 working days

Delivery times 1 - 3 working days

Visitors also bought

Recently viewed products

4,4 based on 41 reviews

Our company

Contact details

De Goudse Gereedschaphandel B.V.

Ambachtweg 19

2841 MA Moordrecht, The Netherlands

Company registration number 86249959

phone number: +31 (0)182787368

E-mail: [email protected]

NL

NL DE

DE FR

FR € EN

€ EN IT

IT NO

NO ES

ES SE

SE DA

DA FI

FI

-

-